Can You Glue Insulation Foam Board Together? Expert Tips Inside

Yes, you can glue insulation foam board together. It’s a common practice in construction and DIY projects.

The right adhesive makes a big difference. Insulation foam boards are popular for their thermal properties. They keep homes warm in winter and cool in summer. Gluing them together can enhance these benefits. Whether you’re building a model or insulating a room, knowing how to properly glue foam boards is vital.

This guide will explore the best adhesives and methods. You’ll learn tips to ensure a strong, lasting bond. Ready to dive in? Let’s get started on making your projects more efficient and durable with glued insulation foam boards!

Introduction To Insulation Foam Boards

Insulation foam boards are a popular choice for both residential and commercial buildings. They help keep your home warm in winter and cool in summer, making them a great investment. But what exactly are these boards, and how can you use them effectively? Let’s dive in!

Types Of Foam Boards

There are several types of insulation foam boards, each with its own unique properties and uses. Here are the main types:

- Polystyrene (EPS and XPS): Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS) are lightweight and provide excellent thermal insulation.

- Polyurethane (PUR) and Polyisocyanurate (PIR): These boards offer higher insulation values and are more resistant to moisture.

- Polyisocyanurate: Often used for its high thermal resistance, making it a top choice for roofing and wall applications.

Common Uses

Insulation foam boards are versatile and can be used in various areas of a building. Here are some common uses:

- Walls: Foam boards can be used to insulate both interior and exterior walls, improving energy efficiency.

- Roofs: Using foam boards on the roof can reduce heat loss and lower energy bills.

- Floors: Insulating floors with foam boards can help maintain a consistent indoor temperature.

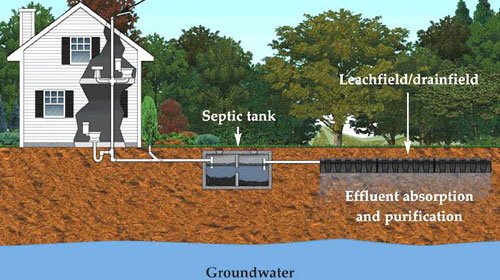

- Basements: These boards are ideal for insulating basements, keeping them dry and warm.

With these types and uses in mind, you might wonder, “Can you glue insulation foam boards together?” The answer is yes, and doing so can enhance their effectiveness. Stay tuned for more tips on how to glue insulation foam boards together in our upcoming sections!

Credit: www.youtube.com

Why Glue Insulation Foam Boards

Gluing insulation foam boards can be a smart choice for many projects. It helps create a strong, continuous layer of insulation. This can improve the energy efficiency of your home. But why exactly should you glue insulation foam boards together? Let’s explore.

Benefits Of Gluing

Gluing insulation foam boards offers several advantages. First, it ensures a tight seal between the boards. This seal prevents air leaks, which can save energy. A well-sealed insulation layer also keeps your home warmer in winter and cooler in summer.

Gluing also adds structural stability. The foam boards stay in place better, reducing movement and gaps. This stability is important in walls and roofs where shifting can cause problems.

Another benefit is the ease of installation. Gluing the boards together can be faster and simpler than other methods. It reduces the need for additional fasteners or mechanical supports.

Common Scenarios

There are many common scenarios where gluing insulation foam boards is useful. One example is insulating a basement. In basements, moisture can be an issue. Glued foam boards can create a moisture barrier, protecting your home.

Another scenario is insulating a garage. Garages often have temperature fluctuations. Gluing foam boards can help regulate the temperature, making the space more comfortable.

Attic insulation is another common use. In attics, air leaks can lead to energy loss. Gluing foam boards can help prevent this, improving the efficiency of your home’s heating and cooling system.

Gluing foam boards is also useful in DIY projects. For example, creating insulated boxes or panels. The possibilities are endless, and the benefits are clear.

Choosing The Right Adhesive

So, you’ve got your insulation foam board ready, but now you need to stick them together. Finding the right adhesive can be a bit tricky. Not all adhesives are created equal, and using the wrong one can make your project go south fast. Don’t worry, though! We’re here to guide you through the maze of adhesives, ensuring your insulation foam boards stick together perfectly.

Types Of Adhesives

There are several types of adhesives you can use for insulation foam boards. Let’s explore the most common options:

- Spray Foam Adhesive: This is a popular choice because it is easy to apply and dries quickly.

- Construction Adhesive: Designed for heavy-duty tasks, it offers a strong bond but can be a bit messy.

- Contact Cement: Known for its strong hold, it is excellent for permanent fixtures but requires careful application.

- Hot Glue: Ideal for smaller projects or temporary fixes, but it may not be suitable for all foam types.

Pros And Cons

Each adhesive has its own set of advantages and disadvantages. Let’s break it down:

| Adhesive Type | Pros | Cons |

|---|---|---|

| Spray Foam Adhesive |

|

|

| Construction Adhesive |

|

|

| Contact Cement |

|

|

| Hot Glue |

|

|

Choosing the right adhesive depends on your project needs. If you’re aiming for a strong, permanent bond, construction adhesive or contact cement might be your best bet. For quicker, less messy jobs, spray foam adhesive or hot glue could do the trick. Remember, each adhesive has its place, so choose wisely!

Preparing Foam Boards For Gluing

So, you’re ready to glue insulation foam boards together? That’s great! But, before diving headfirst into the gluing process, there are a few crucial steps you need to take to ensure a strong bond. Preparing the foam boards is an essential part of the process, and skipping this step can lead to a weak bond that won’t hold up over time. Let’s break it down step by step.

Cleaning The Surface

First things first, let’s talk about cleaning the surface of your foam boards. You might be thinking, “Why do I need to clean foam boards?” Well, a clean surface ensures that the adhesive sticks properly. Dust, debris, and oils can all interfere with the bonding process.

To clean your foam boards, follow these simple steps:

- Brush off: Use a soft brush to remove any loose particles.

- Wipe down: Dampen a cloth with a bit of water and gently wipe the surface.

- Dry thoroughly: Allow the boards to dry completely before moving on to the next step.

It’s as easy as pie! A clean surface is the foundation of a strong bond.

Cutting And Shaping

Now that your foam boards are squeaky clean, it’s time to cut and shape them. You want the pieces to fit together like a glove. Uneven edges can lead to gaps, making it harder for the glue to hold.

Here’s how to get those perfect edges:

- Measure: Use a ruler to measure the dimensions you need.

- Mark: Mark your measurements with a pencil. Precision is key!

- Cut: Use a sharp utility knife or a hot wire cutter for clean cuts. Take your time to avoid jagged edges.

- Sand if needed: If the edges are rough, lightly sand them until smooth.

Remember, a little patience goes a long way here. Think of it as preparing ingredients for a recipe – the better the prep, the better the final dish!

With your foam boards cleaned and perfectly shaped, you’re now ready to move on to the gluing process. Stay tuned for our next section where we’ll dive into the best adhesives to use and how to apply them for a durable bond.

Step-by-step Gluing Process

Gluing insulation foam boards together can be a straightforward task if you follow the right steps. This process ensures your foam boards are securely bonded, providing effective insulation. Let’s walk through the step-by-step gluing process, making sure you understand every detail clearly.

Applying The Adhesive

First things first, you need to select the right adhesive. Not all glues work well with foam boards. Look for an adhesive specifically designed for foam, such as foam board adhesive or construction adhesive. Avoid using super glue as it can damage the foam.

- Clean the Surface: Ensure both foam boards are clean and dry. Dust and debris can prevent proper adhesion.

- Prepare the Adhesive: Read the instructions on the adhesive packaging. Some adhesives might need to be mixed or shaken before use.

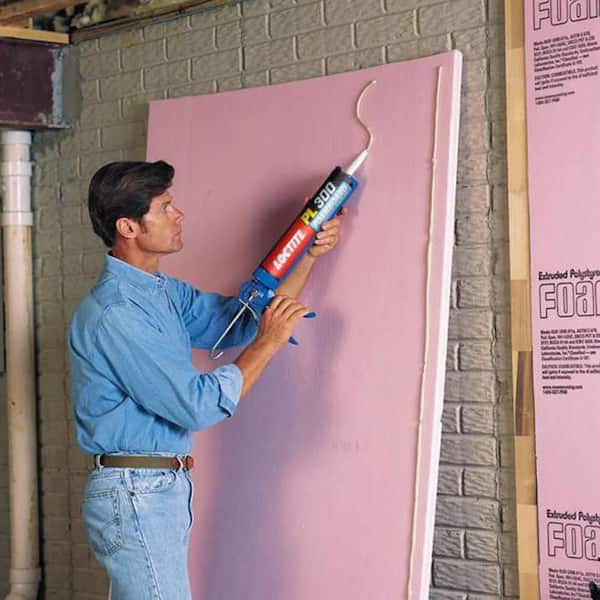

- Apply the Adhesive: Using a caulking gun, apply the adhesive evenly on one side of the foam board. You can use a zigzag pattern for better coverage. Be careful not to use too much adhesive, as it can ooze out when you press the boards together.

Joining The Boards

Now that you have applied the adhesive, it’s time to join the foam boards. This step requires a bit of precision but is quite manageable with the right approach.

- Align the Boards: Carefully align the edges of the two foam boards. You want them to fit together snugly without gaps.

- Press Firmly: Once aligned, press the boards together firmly. Apply even pressure across the surface to ensure the adhesive spreads and bonds well.

- Clamp the Boards: If possible, use clamps to hold the boards together while the adhesive dries. If you don’t have clamps, you can place heavy objects on top of the boards.

- Allow to Cure: Let the adhesive cure for the time specified on the product packaging. This can vary from a few hours to overnight. Patience is key here!

And there you have it! With these steps, your foam boards should be securely glued together, providing the insulation you need. Wasn’t that easier than you thought? Remember, practice makes perfect. So, next time you tackle a similar project, you’ll be a pro!

Curing And Drying Time

Gluing insulation foam boards together requires careful attention to curing and drying time. Allow adequate time for the adhesive to set fully. This ensures a strong bond and effective insulation.

When working with insulation foam board, understanding the curing and drying time is crucial. You don’t want to rush the process and end up with a weak bond. Proper curing ensures the adhesive fully sets, providing a strong and durable connection. Let’s dive into the specifics to help you achieve the best results.Optimal Conditions

For the best curing and drying results, you need to consider the environment. Temperature and humidity play significant roles. Here’s what you should aim for:- Temperature: Between 50°F (10°C) and 75°F (24°C). Extreme temperatures can either slow down or speed up the drying time, which isn’t ideal.

- Humidity: Around 50%. Too much moisture in the air can prolong the drying process, while too little can cause the adhesive to dry too quickly, leading to a brittle bond.

Tips For Faster Drying

We all want to speed things up sometimes, right? Here are a few tips to help your adhesive dry faster, without sacrificing bond strength:- Use a fan: A gentle breeze can help evaporate moisture, speeding up the drying process. Just be careful not to blow too hard, or you might end up with dust and debris sticking to your glue.

- Apply thin layers: Thicker layers of adhesive take longer to dry. Apply a thin, even layer for quicker curing.

- Choose a fast-drying adhesive: Some adhesives are specifically formulated to dry quicker. Check the label for drying times and choose one that suits your needs.

- Warm the surfaces: Slightly warming the foam boards before applying adhesive can help speed up drying. A hairdryer on a low setting works wonders for this. Just don’t overdo it, or you might melt the foam!

Common Mistakes To Avoid

Gluing insulation foam boards together can be tricky. Many people make common mistakes that affect the final result. Here, we will discuss the most frequent errors and how to avoid them.

Incorrect Adhesive Use

Choosing the wrong adhesive is a common mistake. Not all glues work well with insulation foam boards. Some adhesives can even damage the foam. Always check the product label. Make sure the adhesive is suitable for foam boards. Using the right glue ensures a strong bond.

Poor Surface Preparation

Proper surface preparation is crucial. Dirty or uneven surfaces can weaken the bond. Always clean the foam boards before applying glue. Remove any dust or debris. Ensure the surface is dry and smooth. This step helps the adhesive stick better.

Credit: www.homedepot.com

Expert Tips For A Strong Bond

Gluing insulation foam board together can be a bit tricky if you don’t know the right techniques. But don’t worry! In this section, we’ll share some expert tips to help you achieve a strong bond. Whether you’re working on a home project or insulating a larger area, these tips will ensure your foam boards stay securely in place.

Ensuring Even Pressure

One of the most important steps in gluing insulation foam board together is ensuring even pressure. This helps the adhesive spread evenly and creates a stronger bond. Here’s how you can do it:

- Use Weights: Place some weights on top of the foam boards after applying the adhesive. Books, cans, or anything heavy will work.

- Clamps: If you have clamps, use them to hold the boards together. Make sure they are spread evenly across the surface.

- Press Firmly: When first joining the boards, press them together firmly. This initial pressure is crucial for a good bond.

Remember, the goal is to distribute the pressure evenly across the entire surface of the boards. This will help the adhesive work its magic!

Reinforcing Joints

Even with a strong adhesive, sometimes the joints between foam boards need a bit of extra reinforcement. Here are some tips to make those joints extra sturdy:

- Apply Extra Adhesive: Don’t be shy with the glue at the joints. Apply a bit more than usual to ensure a strong hold.

- Use Tape: After the adhesive has set, reinforce the joints with some tape. Duct tape or foam board tape works well.

- Insert Dowels: For an added layer of strength, insert small wooden dowels into the joints. This helps keep the boards aligned and secure.

These simple steps can make a big difference in the durability of your project. So, don’t skip them!

By following these expert tips, you’ll be able to glue insulation foam board together with confidence. Your projects will be stronger, more durable, and you’ll save time and money in the long run. Happy gluing!

Alternative Methods

Gluing insulation foam boards together can be a bit tricky, especially if you’re trying to achieve a seamless finish. Luckily, there are alternative methods that can provide just as good, if not better, results. In this section, we will explore some practical and effective ways to join foam boards without relying solely on glue. From mechanical fasteners to tape and other creative solutions, these methods can make your insulation project easier and more efficient.

Mechanical Fasteners

One of the most reliable methods to join insulation foam boards is using mechanical fasteners. This approach is particularly effective for larger projects or areas exposed to varying temperatures and humidity levels. Mechanical fasteners, such as screws, nails, or specialized clips, can securely hold the foam boards in place.

- Screws and Washers: Use screws with large washers to distribute the pressure evenly across the foam surface.

- Foam Board Clips: These clips are designed to hold foam boards together without damaging the material.

- Brackets: Metal or plastic brackets can provide additional support and stability for the foam boards.

By using mechanical fasteners, you ensure a strong and durable connection that can withstand environmental changes and physical stress.

Tape And Other Solutions

If you’re looking for a quicker and less invasive method, tape and other adhesive solutions can be quite effective. Taping foam boards together is a simple and efficient way to join them, especially for smaller projects or temporary setups.

- Construction Tape: Use high-quality construction tape designed for insulation materials. This tape provides a strong bond and is resistant to moisture and temperature changes.

- Double-Sided Tape: This can be an excellent option for lightweight foam boards, offering a clean and invisible connection.

- Foil Tape: If you need extra durability, foil tape can provide added strength and is particularly useful for sealing seams and gaps.

Apart from tape, other adhesive solutions such as spray adhesives or contact cement can also be effective. Just ensure the adhesive is compatible with foam insulation to avoid any chemical reactions that could damage the material.

In conclusion, whether you choose mechanical fasteners or adhesive solutions, these alternative methods can help you achieve a sturdy and efficient connection for your insulation foam boards. Experiment with different techniques to find the one that works best for your specific project and enjoy the process of creating a well-insulated space!

Credit: www.printmoz.com

Frequently Asked Questions

Can You Glue Foam Board Insulation Together?

Yes, you can glue foam board insulation together. Use foam board adhesive or construction adhesive specifically designed for foam.

How To Attach Two Foam Boards Together?

To attach two foam boards, use a strong adhesive like foam board glue or double-sided tape. Apply evenly on one board and press them together firmly. Ensure alignment for a secure bond.

What Is The Best Way To Glue Two Pieces Of Foam Together?

Use a foam-specific adhesive like 3M Foam Fast 74. Apply evenly to both surfaces. Press firmly together. Allow drying time as per instructions.

What Glue Will Stick Foam Together?

Use foam-specific adhesive like 3M Spray Foam Adhesive, UHU Por, or Gorilla Glue. These provide strong, lasting bonds.

Conclusion

Gluing insulation foam boards together is quite simple. Use the right adhesive. Ensure surfaces are clean and dry. Apply adhesive evenly for a strong bond. Press the boards firmly together. Let them dry completely before use. This method saves time and ensures efficiency in your project.

Properly glued boards improve insulation effectiveness. Tackle your insulation project with confidence.

My name is Maria, A professional merge game player with years of experience mastering games like Merge Dragons, Merge Gardens, Merge Mansion, and more. My passion for uncovering the best strategies, solving tricky puzzles, and discovering hidden secrets led her to create MergeGameplay.com.